Ozone Generator for Meat: Revolutionizing Safe and Effective Meat Disinfection

Using an ozone generator for meat has become a breakthrough solution for ensuring food safety and extending the shelf life of meat products. As consumers demand safer and more natural food preservation methods, ozone has emerged as a reliable, chemical-free alternative to traditional disinfectants. Meat producers, processors, and cold-chain suppliers are rapidly adopting ozone technology to meet growing hygiene standards and reduce spoilage.

How Ozone Works

Ozone is a triatomic oxygen molecule with high oxidative power. It destroys pathogens by breaking down cell membranes and disrupting DNA. After reaction, ozone decomposes back to oxygen, leaving no harmful residue.

It’s generated on-site using corona discharge or UV methods—making it a sustainable and storage-free solution.

Benefits of Using Ozone Generators for Meat Disinfection

1. Kills Harmful Pathogens

Ozone is effective against E. coli, Salmonella, and Listeria. Studies show that gaseous ozone (154 mg/m³ for 3 hours at 0–4°C) reduces total aerobic bacteria by 0.5 log and E. coli by up to 1.0 log on beef surfaces.

2. Improves Meat Quality

By controlling microbial growth, ozone helps maintain the meat’s natural color, texture, and flavor—essential for consumer satisfaction and brand reputation.

3. Extends Shelf Life

For example, gaseous ozone treatment (5–10 mg/L) extended the shelf life of refrigerated chicken by 6 days while keeping bacterial counts below 7 log CFU/g for 16 days.

4. Cost-Efficient Long-Term

Though initial investment in an ozone system may be higher, it reduces ongoing costs such as chemical disinfectants, water usage, and spoilage-related waste.

5. Eco-Friendly and Chemical-Free

Ozone breaks down into oxygen, producing no harmful byproducts—an ideal solution for clean-label and sustainable meat processing.

6. Regulatory Compliance

Ozone is GRAS-certified by the FDA and approved by the USDA for direct contact with food, ensuring safety and compliance with industry standards.

How to Apply Ozone in Meat Processing

Gaseous Ozone:

Used for surface disinfection, packaging, and cold storage. It continuously sanitizes meat during transportation or refrigerated storage.

Aqueous Ozone:

Ozone dissolved in water is ideal for rinsing meat or cleaning conveyor belts. A 12 ppm ozone spray (90 sec every 30 minutes, 4.6°C–5.6°C) reduced E. coli O157:H7 by 1.46 log.

Safety Considerations

- Limit Exposure: OSHA recommends limiting ozone concentration to 0.1 ppm over 8 hours.

- Proper Ventilation: Run ozone systems in well-ventilated or unoccupied areas to prevent inhalation risks.

- Training: Staff must be trained in ozone system operation and safety.

- Material Compatibility: Use ozone-resistant materials like stainless steel to avoid corrosion.

- Follow Regulations: Ensure usage aligns with FDA/USDA guidelines.

How to Choose the Right Ozone Generator

- Capacity Matching: Choose equipment that fits your processing volume.

- System Type: Gaseous for air disinfection, aqueous for wash-down applications.

- Certifications: Look for FDA/USDA-compliant machines.

- After-Sales Support: Ensure the manufacturer offers tech support and maintenance.

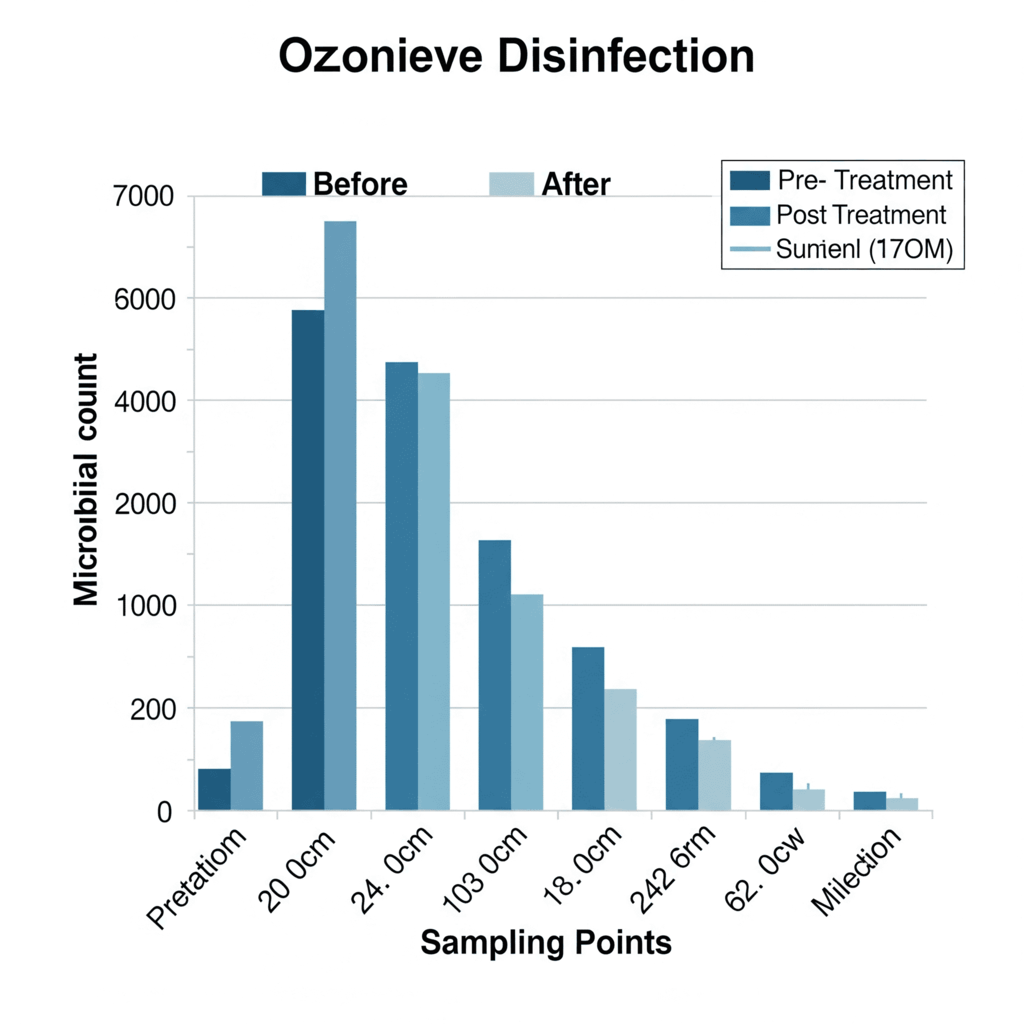

Real-World Case Studies

| Meat Type | Pathogen | Ozone Type | Concentration | Treatment | Effectiveness |

|---|---|---|---|---|---|

| Beef | E. coli O157:H7 | Aqueous | 12 ppm | 90 sec spray, every 30 min for 12 hrs | 1.46 log reduction |

| Chicken | Aerobic bacteria | Gaseous | 5–10 mg/L | Refrigerated | Shelf life +6 days |

| Turkey | Enterobacteriaceae | Gaseous | 10 g/m³ | 6 hours at 22°C | 2.3 log reduction |

Conclusion

Ozone generators present a groundbreaking and eco-friendly solution for meat disinfection. By effectively eliminating harmful pathogens, they help extend product shelf life while significantly reducing the need for chemical preservatives. When properly implemented with the right system design and safety protocols, ozone technology enables meat processors to consistently meet the highest standards of food safety.

According to the FDA, ozone is officially recognized as a safe antimicrobial agent for use in meat and poultry processing. Furthermore, research published by the US National Library of Medicine confirms that ozone treatment is highly effective in reducing microbial contamination on meat surfaces—without leaving behind any chemical residue.

For more details, visit our product site at ljozone.com to explore tailored ozone solutions for meat processing. You can also read more about how ozone works in food safety in our in-depth guide.